Proposal to facilitate SCIP notification for Automotive and Industrial Batteries Introduction

With this paper EUROBAT intends to support European battery industry, the European Commission and the and European Chemicals Agency to facilitate and streamline the process to submit notification to the SCIP[1] Database.

Batteries play a crucial role in supporting the European Green Deal targeting the transition towards a decarbonized society and climate-neutral economy by 2050. They are recognized as key enablers for decarburization in transport, energy, logistics, production and telecommunications, supporting the energy transition and contributing to the improvement of a multitude of applications.

Four battery technologies are now available on the market for Automotive and Industrial batteries: lead, lithium, nickel and sodium-based batteries, all with their specific characteristics and advantages for a given application.

Design and Application

Automotive and Industrial batteries are designed according to international standards and user/customer requirements. The user/customer makes a choice which electrochemical system provides the best solution for its application. With that decision the customer either accepts or even defines the product design and application, hence already knows about the content of a substance of very high concern at the earliest stage possible.

Hence more information specific information (e.g. on the level of a part number), will not deliver any additional benefit for the customer.

Also it has to be noted that products are documented under multiple part numbers. This is due to the fact that design features which are not relevant for composition (e.g. color of box or outer casing, customer specific logo’s) require individual part numbers. This multiplies the part numbers (the number of potentials SCIP notifications) without additional information content relevant for the purpose of the SCIP database.

End-of-Life Management

Automotive and Industrial batteries are subject to existing Battery Directive, this defines design principles, extended producer responsibility and end-of-life principles. Essential elements of the end-of-life principle are the:

- requirement to take back and collect separately

- ban to landfill spent batteries

- obligation to recycle under recycling efficiency target specific to the electrochemical system

Automotive and Industrial batteries reach the end of their useful life and become waste predominantly at commercial sides. This ensures that, as required by the Batteries Directive, these batteries are handed over to specialized companies, authorized by competent authorities to manage hazardous waste, who ensure the safe transport of the end-of-life batteries and their remittance to fully permitted recyclers. The valuable materials contained within can easily be accessed by recycling professionals who have the expertise and training to deal with their recovery and handling.

The recycling processes are specific to the electrochemical system of the spent battery. The operators of the processes are well aware of the composition of the product; hence they are already aware which electrochemical systems contains a substance of very high concern.

Information on level of individual part numbers are not relevant here.

Proposal to facilitate SCIP notification for Batteries Grouping

The similarity in the design and composition of batteries belonging to the same electrochemical system qualifies batteries for a grouping approach. This grouping includes all necessary information; hence it is qualified to be used as “primary article identifier”. Also this grouping corresponds with the TARIC Code, another mandatory entry under the SCIP notification.

Grouping of similar composed products will reduce the efforts[2] to notify without compromising the REACH Article 33 information requirement or WFD Article 9 notification requirement.

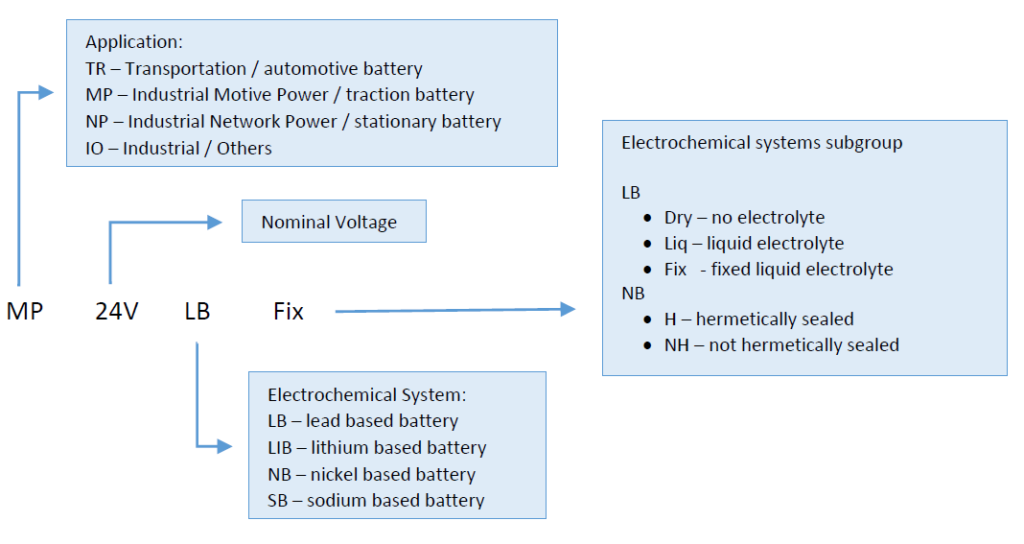

A grouping proposal may use the following code:

The above mentioned example describes all 24V lead based traction battery with a fixed electrolyte.

According to this scheme the grouping “IO 18V NB H” describes all hermetically sealed 18V nickel based batteries that are used for industrial purposes.

The corresponding TARIC code is determined by the electrochemical system, the application and technical properties (e.g. liquid/none liquid electrolyte, hermetically sealed/not hermetically sealed, hence the above described grouping also facilitates the allocation to the TARIC Code.

Notifications that will use this grouping as the primary article identifier (“other”) and mention the brand name under “Article name” will allow to identify all substances of very high concern to all involved stakeholders while optimizing the amount of datasets to be produced.

Data format

Even if the under a grouping scheme, the exchange of data should be processed via IT systems that had been proven for its robustness and are well established. The exchange should be processed via CSV formatted data.

Summary

EUROBAT strongly recommend to consider the following to improve and facilitate the notification process:

- Accept grouping of notifications rather than going for one notification per part number

- Facilitate import/export by using CSV format

[1] SCIP Database: Database of information on substances of concern in articles as such or in complex objects (products)

[2] An assessment of one EUROBAT member Company concludes that the grouping approach will reduce the number of notifications from a little above 10.000 to 34 notifications.