How higher ambitions for decarbonisation leads to innovation in the battery separator industry

In recent years, EU policy-makers have increasingly acknowledged the essential role that batteries play for decarbonisation and are aspiring to develop a battery eco-system in Europe. Separator manufacturers are a critical part of this value chain, facilitating innovations in battery technologies to serve new applications and improve existing ones.

As an integral component of batteries, separators support the contribution of key battery technologies to the achievement of the EU’s ambitious decarbonisation goals.

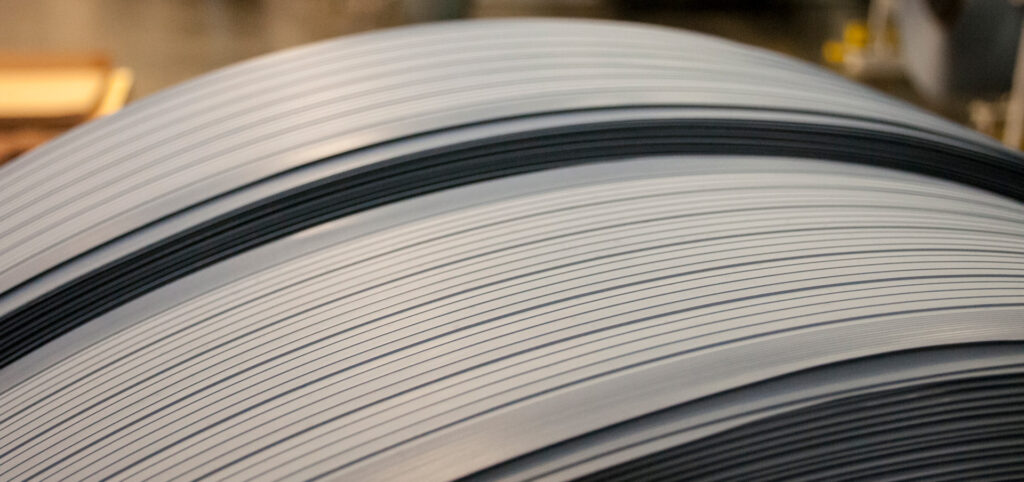

Separators are microporous materials that are placed between the anode and cathode in a battery to keep the two electrodes apart, whilst allowing the transport of ions. They work for a long period in an aggressive environment, so the separator and the structure of the separator must withstand certain aggressive working conditions that ensure it preserves its functionalities over time. Since they do two opposite things at once, to both prevent and allow the flow of electricity, the design of the separator can be challenging.

Nullo Madella, Director of Sales at Microporous, said: “We are continuously working on raw materials, on the specific formulations of our separators that provide improvements in oxidation resistance and other physical properties that are critical to the life of the separator and can influence the electrical performance of the battery.”

Innovations in separators and their materials often go hand in hand with innovations and improvements in battery technologies. This either supports new end-user applications or improves existing ones, contributing to the role of batteries as a bridge to Europe’s low carbon future.

The development of enhanced flooded batteries (EFB) is a prime example of how separator innovations contribute to advanced battery technologies that serve new applications that can have a big impact on lowering carbon emissions.

The start-stop system, which emerged in the early 2000s, detects when the car is stationary and automatically stops the engine, resulting in a huge increase in the number of times cars are starting and stopping every day. This can reduce carbon emissions by around 3-8% and the environmental benefits can be significant in urban areas. To serve this key technology, batteries needed a longer life in harder work conditions and cycle life, so required a separator with premium electrical resistance, longer durability and higher oxidation resistance.

Graeme Fraser-Bell, VP – Li Sales & Market Development at Entek, said: “The start-stop functionality had a significant impact on the battery, which really drilled down into the performance of the separator. The separator had to be re-engineered for enhanced flooded batteries with reduced thickness, higher porosity and lower impedance. If you look at the growth of start-stop now, especially in cities, you’re looking at substantial reductions in CO2 and other particulates.”

These innovations in separators cut across all battery technologies. With the growth of electric vehicles and the phasing out of internal combustion engines in Europe, innovations in separators for lithium batteries have also come to the fore. The separator has got thinner and the structure has changed. It is now coated on both sides with ceramics that control the thermal integrity and contribute to oxidation resistance, voltage resistance and dendritic formation, requiring an acute understanding of polymer processing, chemistry, ceramic processing and chemical engineering.

This innovation potential of separators, as a core component of key battery technologies that support decarbonisation through a range of applications – from automotive, material handling and logistics to off-road motive power and stationary energy storage – comes out of a close working relationship with battery manufacturers. Innovation is driven by the requirements of the final application, so separator companies work closely with battery manufacturers to understand the development pathway for the separator, such as the breakdown voltage, cycle life and energy density, which results in different combinations of materials for specific batteries and their applications.

Membership of industry associations like EUROBAT further strengthens this collaboration, where separator companies listen to the battery manufacturers to understand the latest developments, future innovations and challenges of the industry, and ultimately to help meet their needs across all battery chemistries.

As part of the battery value chain, separator companies also have a strong commitment to sustainability and the circular economy, in minimising waste, optimising production processes and achieving the lowest possible emissions, as well as localising the material supply base.

Marcus Ulrich, Head of Sales Battery Separators at Ahlstrom-Munksjö, said: “It is in our DNA to look for sustainability, which is one of the main short- and long-term drivers across all applications. We try to minimise our carbon footprint and minimise our energy losses when producing separators, as well as use water sustainably and look at ways to reduce our resource use.”