EUROBAT position paper on the Batteries Regulation: recommendations to policy-makers

1. Support the production of all battery technologies in Europe

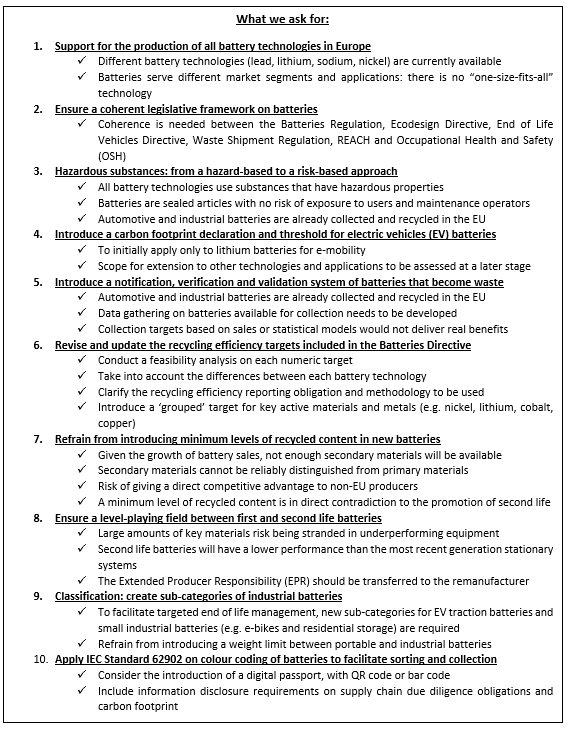

Batteries are critical to the fight to decarbonise our economy and tackle climate change. All battery technologies — lead, lithium, nickel and sodium — are needed to support the decarbonisation of the transport, energy, logistics, production and telecommunications sectors. No single battery technology can meet all the challenges of end-user demands and combine high power and energy density, long life, reasonable cost, excellent safety and minimal environmental impact.

Europe must take a lead in designing and building the most environmentally sustainable energy storage solutions and supporting the development of its battery industry. To do so, policy-makers, citizens, associations and industry must work together to remove legislative and market barriers. They must instead promote the development of a favourable environment in which the European battery industry can flourish, delivering growth, innovation and increased employment.

The upcoming proposal for a new Batteries Regulation, replacing the 2006 Batteries Directive, will be a cornerstone of this legislative environment, ensuring that the objectives of competitiveness and sustainability, or competitiveness through sustainability, are both met. To do so, EUROBAT has developed the following recommendations, taking into account all aspects of a battery's lifecycle, from production to end of life management.

2. Ensure a coherent legislative framework on batteries

Today, several pieces of legislation have batteries within their scope, creating legislative overlaps, lack of business certainty and incoherent policy directions. Two directives currently address the collection and recycling of batteries: the Battery Directive and the End-of-Life Vehicles Directive. The proposal for a new Batteries Regulation will provide an opportunity to make it more reflective of technological developments and the environmental sustainability of batteries rather than focused disproportionately on the hazardous properties of substances.

Requirements on recycling in the End-of-life vehicles (ELV) Directive have resulted in some overlaps with those presented in the Battery Directive and we believe that only the latter should be the reference on this topic. The ELV Directive also introduces a prohibition on the use of hazardous substances in vehicles, with exemptions given in the case that substitution is not technically feasible. In the future, wider socioeconomic factors and sustainability considerations must also be among the criteria for these exemptions.

Also, the Waste Shipment Regulation is relevant in this sense: today, in certain cases recycling of batteries outside of the EU takes place in unregulated facilities, with poor environmental, health and safety practices. Amending the Waste Shipment Regulations to facilitate imports of waste batteries into the EU could help in this regard.

3.Hazardous substances: from a hazard-based to a risk-based approach

All battery technologies use substances that have hazardous properties: for instance, lead, cobalt, nickel and lithium are commonly included in batteries. However, batteries are sealed articles without any intended release of any of the substances used in their manufacture, which means there is no risk of exposure for users. Moreover, automotive and industrial batteries are not landfilled, incinerated or improperly disposed of. Exposure risks of workers along the value chain is already addressed through the existing EU legislative framework (e.g. REACH & Occupational Health and Safety Legislation).

Right now, the Batteries Directive identifies a limited number of substances as hazardous using unclear criteria, prohibits their use or encourages substitution. This approach is disproportionate to the actual exposure risk and an assessment of this would be more effective and proportionate. In line with other existing legislation, such as REACH, the risk assessment should be supplemented by an evaluation of socioeconomic costs and benefits, and also include wider sustainability or life cycle considerations to ensure that European battery manufacturing remains competitive in the global marketplace.

4. Introduce a carbon footprint declaration and threshold for electric vehicles batteries

The key environmental impact of EV batteries takes place during production. For this reason, it will be paramount to have a clear indication of the carbon footprint for this class of batteries to be able to promote the greenest batteries and give clear indications to consumers. We strongly believe that Europe should take the lead in producing the most sustainable batteries and, to do so, we need clear instruments to assess their footprint. The introduction of a minimum threshold to exclude the worst performing lithium batteries from the market should also be considered.

Currently, a Product Environmental Footprint Category Rules is available for lithium batteries for mobility applications. This instrument could be a good basis to develop that indicator. However, this instrument is not available for other battery technologies (lead, nickel, sodium) and applications (e.g. for stationary storage system). For this reason, we support the introduction of a carbon footprint declaration and threshold for lithium batteries for EV applications. The development of similar instruments for other battery technologies and applications could be assessed at a later stage.

5. Introduce a notification, verification and validation system of batteries that become waste

All automotive and industrial batteries, including EV traction batteries, are already covered by the implicit 100% collection target outlined in the Batteries Directive[1]. These batteries are already collected and recycled in the EU:

- Automotive batteries are lead-based. These batteries have a positive value at the end of their life, and all economic actors have a direct economic interest in recycling them. Recycling lead is relatively simple and cost-effective and, in most of the applications where lead is used, especially lead-based batteries, it is possible to recover it for use over and over again without any loss in quality. It is widely acknowledged that the collection and recycling of automotive lead-based batteries operates, effectively, in a closed loop. EUROBAT has already demonstrated in a 2014 study[2] that 99% of automotive lead-based batteries are collected and recycled in the EU, making it one of the most recycled consumer products in the EU and even at a global level.

- Industrial batteries are generally bulky, heavy and used in a business-to-business context, and therefore handled by professionals at the end of their life. Despite the lack of data, it is a generally common understanding that the collection and recycling rate of industrial batteries is close to 100%, as recognised also by the European Commission Service[3].

However, it must be recognised that reliable data on battery collection is not available for several reasons – improper filing, unclear definitions or methodologies and differences among member states. To address this issue, we should look at batteries available for collection, not batteries placed on the market. Not all automotive and industrial batteries produced in Europe are available for collection: some are exported outside of the EU, as primary or second-hand products, while others are still in operation, sometimes for decades, which makes it extremely difficult to set up a collection target. Besides, the number of “batteries available for collection” should not be calculated based on a statistical model, but properly based on those batteries that reach the end of their life.

For these reasons, EUROBAT supports the introduction of a notification, verification and validation system of batteries that become waste[4]. This system should apply to all industrial batteries, including EV traction batteries but excluding light mobility batteries (eBikes, eScooters, etc.). This system would allow the gathering of data on batteries collected across the EU, flagging possible local problems in the collection system.

6. Revise and update the recycling efficiency targets included in the Batteries Directive

Currently, the Batteries Directive includes recycling efficiency targets for lead-based (65%) and nickel-based (75%) batteries. Other battery types, including lithium-based batteries, have a generic 50% target. Considering technological developments over the past years, we believe that these targets should be revised, taking into account the declared recycling efficiency values provided by the Member States. The revision should anyway take into account the following principles:

- Conduct a feasibility analysis on each numeric target, considering both current performances and possible future developments and improvements of recycling processes.

- Take into account the differences between each battery technology to select an appropriate target: for instance, the recycling efficiency rates of lithium NMC batteries (nickel-manganese-cobalt) are not the same as lithium LFP batteries (lithium ferrophosphate). We cannot accept the principle that what works for one chemistry will also work for others without having targeted analysis on each technology.

- The current underlying calculation methodology for recycling presents problems. The quality of data provided by the Member States on recycling efficiency is questionable: it cannot be reasonable to read, as we do today, the Member States reporting (highly unrealistic) recycling efficiencies for processes that are not operating in their territory. The Regulation should clarify the recycling efficiency reporting obligation and methodology to be used by the Member States, and also what is accounted for in recycling. It is of course fundamental to ensure that recyclers in third countries (outside the EU) also have to prove the compliance of their activities according to EU standards.

In addition to the current recycling calculation methodology, based on the weight of the battery, material recovery targets for key metals (e.g. cobalt, nickel, lithium) could be proposed. In this case, it would be paramount to conduct a feasibility analysis on these targets, and allow the possibility to develop new recycling processes without picking a winner: certain processes allow a higher share of a particular metal over others, and recyclers should be granted the flexibility to prioritise their targets or achieve higher specialisation. This flexibility would enable innovation and make the proposal adaptable to future evolutions in the battery chemistry, as well as in relation to market demand.

EUROBAT, therefore, supports a “grouped” target for all active materials together instead of individual targets. The objection that this might result in economically less valuable materials not being recycled could be addressed by including a weighting system in the calculation to give more relevance to specific metals.

7. Refrain from introducing minimum levels of recycled content in new batteries

Having minimum levels of recycled content in batteries might seem an appealing change in terms of environmental benefits. However, once we start carefully assessing the pros and cons of such a proposal and the complications of setting up and properly implementing it, it becomes clear that it would be extremely difficult to obtain environmental benefits at all, for the following reasons:

- Material availability: given the growth of battery sales, not enough secondary materials will be available up to 2035.

- Secondary materials cannot be reliably distinguished from primary materials: it is, therefore, unclear how this target could be tested and enforced, above all for batteries imported into the EU.

- International competition: some non-EU producers have supplied e-mobility batteries for some years, so there are some used batteries already coming back for recycling. Using this secondary material flow, Asian manufacturers could develop and manufacture “EU specific products” to meet the regulatory requirements set for recycled content using these secondary raw materials, with a direct competitive advantage.

- Closed-loop vs open-loop: a closed-loop system is not necessarily preferable to an open-loop system. Metals recovered from batteries are used in other applications. Forcing them to be used to produce new batteries instead would distort the market and force other sectors to look elsewhere for their raw materials with zero net societal gains.

- The target cannot be placed on individual products: for instance, the level of secondary lead in individual lead-acid batteries varies from >50 to 100%. For the entire industry, the best estimate is 85% of secondary lead used in new battery manufacture. A key obstacle is the specification for certain sealed products, which often require some primary lead for the active material (a little below 50% of the entire lead content).

- A minimum level of recycled content is in direct contradiction with the promotion of second life – we can either reuse the materials OR the battery, not both at the same time.

8. Ensure a level-playing field between first and second life batteries

The regulatory framework on second life batteries should be clarified, in particular regarding Extended Producer Responsibility (EPR) and access to the Battery Management System (BMS). Refurbishing a battery is a complex process that modifies the BMS and changes the use and purpose of the battery. Since the battery was produced for a different use, the original manufacturer cannot be held responsible and liable for misuse of the battery: for this reason, the EPR should pass to the remanufacturer, who should be responsible for the end of life management of the battery.

We, therefore, see some merit in the proposal that batteries become waste after first life, but batteries for second life cease to be waste and re-acquire product status if certificates on the state of health and other information are provided and the PRO (or OEM) establishes a contract with a remanufacturer making Input-Output access to BMS available to the remanufacturer. Since access to BMS is a very sensitive point, with clear implications on safety, data protection and intellectual property, we believe that access to BMS should be regulated by contracts and not mandated by legislation.

Once the regulatory framework is clarified, we should also consider the environmental implications of second life. EV batteries that have reached the end of their life are usually approximately 10-12 years old, and it can therefore be expected that they were designed 15-18 years earlier. At this point in the future, the performance of current batteries is likely to have improved significantly over this period of time (approximately 5 generations in between), and it would be a pity to see valuable materials stranded in underperforming assets. Better performance (with longer lifetime) of new stationary batteries compared to second life batteries would deliver additional environmental benefits.

Besides, second life applications may result in the risk of having valuable materials parked in those applications instead of having more efficient use in a state of the art designed first life application. Second life would be in direct contradiction with the principle of resource efficiency, but also with minimum levels of recycled content.

For these reasons, we do not believe that any positive bias should be granted to second life batteries. The decision between recycling and second life should be left to the market, above all because not enough evidence is provided on the environmental benefits of second life batteries.

9. Classification: create sub-categories of industrial batteries

The Batteries Directive currently divides batteries according to their use: portable, automotive (for starting, lighting, and ignition) and industrial batteries (for industrial use, traction and stationary applications). This classification system is overall still valid, but it might require some adjustments.

- A sub-category of industrial batteries for EV traction batteries should be created. Given their growing importance and market share, it makes sense to treat them separately and avoid the risk of diluting the relevance of other industrial batteries.

- Batteries for light mobility (e.g. e-bikes) and for home storage systems: a new sub-category “small industrial batteries” should be created to include “industrial batteries which are used in private homes and whose replacement from the appliance which it powers is conducted by the private household/consumer, rather by an outside professional”. This new sub-category would allow the setting of targeted EPR logistical systems to properly serve private households/consumers.

The possibility of clarifying the distinction between portable and industrial batteries is also a recurring discussion. Small industrial batteries are designed to be handled by professionals. It does not make sense to consider them as portable and force them to respect guidelines, restrictions and regulations developed for a different product type. A labelling or QR code on batteries could be an option to allow a clear assignment to the categories portable and industrial, as proposed by the consultants.

We are against a weight limit to differentiate portable and industrial batteries. This possibility was already discussed in 2006 and then discarded for several reasons. For instance, it is quite difficult to establish a unique weight limit to take into account the different battery technologies used for a large variety of segments, each one with its own requirements and characteristics. In Europe, the United Kingdom has merely a guideline (and neither legislation nor a regulation!) in place with thresholds by weight as criteria for distinguishing between industrial and portable batteries.

A clearly unintended consequence of this proposal would be to consider industrial batteries below the weight threshold as portable batteries. Since there is a significant number of industrial Ni-Cd batteries with low weight, including batteries for back-up power to civilian aircraft and for the railway market, this proposal would simply remove them from the market because of the cadmium restriction placed on portable batteries.

10. Apply IEC Standard 62902 on colour coding of batteries to facilitate sorting and collection

EUROBAT supports the application of the IEC Standard 62902 on colour coding of batteries to facilitate sorting and collection. The option of a digital passport is potentially interesting, but it should be clarified which kind of information would be included, the access level and the tool (QR code or bar code) in coordination with the Global Battery Alliance initiative. EUROBAT supports the inclusion of due diligence obligations and carbon content information for those technologies where a methodology has already been developed (EV traction batteries). Additional methodologies to calculate the carbon footprint could also be developed for other technologies and applications, and then included in the legislation when available.

EUROBAT is the association for the European manufacturers automotive, industrial and energy storage batteries. EUROBAT has more than 50 members from across the continent comprising more than 90% of the automotive and industrial battery industry in Europe. The members and staff work with all stakeholders, such as battery users, governmental organisations and media, to develop new battery solutions in areas of hybrid and electro-mobility as well as grid flexibility and renewable energy storage.

[1] The Batteries Directive includes a collection target for portable batteries but not for industrial and automotive batteries. However, it obliges battery producers to set up end of life solutions as detailed in Art. 8.3 and 8.4. This obligation, combined with the ban on landfilling and incineration (Art. 14), results in an implicit 100% collection target for automotive and industrial batteries.

[2] The Availability of Automotive Lead-Base Batteries for Recycling in the EU, https://www.eurobat.org/wp-content/uploads/2021/09/ihs_eurobat_report_lead_lores_final_2.pdf

[3] COMMISSION STAFF WORKING DOCUMENT on the evaluation of the Directive 2006/66/EC on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC SWD(2019)1300 https://ec.europa.eu/environment/waste/batteries/pdf/evaluation_report_batteries_directive.pdf

[4] EUROBAT proposal for a notification, verification and validation system of batteries that become waste, https://www.eurobat.org/wp-content/uploads/2021/09/EUROBAT_proposal_for_a_notification_verification_and_validation_system_of_batteries_that_become_waste.pdf